R.W. Holland is a manufacturer of hairpin heat exchangers and suction and line heaters. The designs they are known for are well suited for the petroleum, petrochemical, chemical and power industries.

R.W. Holland has been around since the early 1970’s. They are an ASME code certified manufacturer that offers standard or custom-built equipment. R.W. Holland’s manufacturing facility is located in Tulsa, Oklahoma.

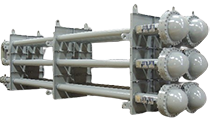

Hairpin Heat Exchangers:

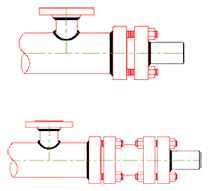

The Holland Petrofin Patented Closure

The Holland Petrofin Patented Closure

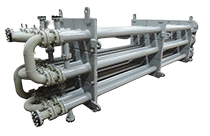

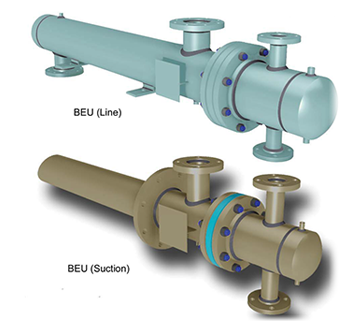

Suction Heater Details:

Line Heaters Details:

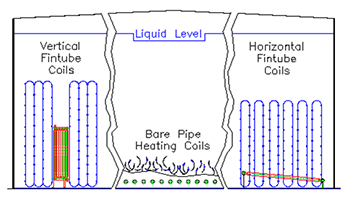

R.W. Holland’s Tank Heating Coils are fabricated with fintubes having the orientation of the fin in the direction of the convection currents in the tank. When the fluid next to the fintube is heated it rised rapidly die to the lower density. The colder fluid at the top of the tank falls to the bottom, creating a thermosyphon action in the tank.

Providing tank heating coils with the fins longitudinally for vertical coils and helically for horizontal coils is the most effective heat transfer surface because the fluid rising vertically passes between the fins, not across the fins.

since Holland Tank Heat Coils are supported off the tank floor and tank fluid is kept in motion by the thermosyphon effect, sediment remains in suspension and the heating coils, tank walls and the floor are kept clean.

Bayonet Coils (Horizontal):

Horizontal Coils (For tanks with low liquid levels):

Vertical Coils:

Atmospheric Air Cooler: